Ti-doped Fe2O3 Photoanodes on Three-Dimensional Titanium Microfiber Felt Substrate for Photoelectrochemical Oxygen Evolution Reaction

Dewangga Oky Bagus Apriandanu, Satoshi Nakayama, Kento Shibata, F. Amano*,

Electrochimica Acta, in press, 2023,

https://doi.org/10.1016/j.electacta.2023.142434

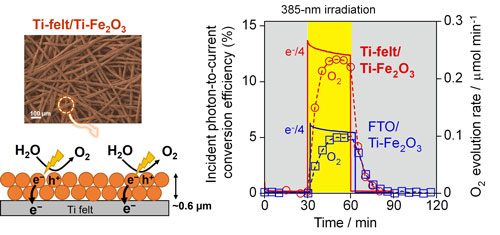

The macroporous structure of conductive substrates with large surface areas is crucial for fabricating semiconductor electrodes that offer better photoelectrochemical (PEC) performance in the water-splitting reaction. In this study, three-dimensional (3D) titanium microfiber felt (Ti felt) was used as a conductive substrate to prepare a Ti-doped Fe2O3 photoanode via a hydrothermal method with a two-step annealing treatment in air and argon atmospheres. Compared to conventional two-dimensional (2D) substrates, such as fluorine-doped tin oxide (FTO)-coated glass and Ti sheets, the loading amount of Fe2O3 on Ti felt was 2–5 times higher for a similar substrate geometric area. The thickness of Fe2O3 on the Ti felt (~0.6 µm) was less than that on the 2D substrates. Ti-doped Fe2O3 on Ti felt (Ti-felt/Ti-Fe2O3) exhibits a higher photocurrent density than FTO/Ti-Fe2O3 and Ti-sheet/Ti-Fe2O3. Mott–Schottky analysis shows that the donor density of Ti-felt/Ti-Fe2O3 (8.58 × 1021 cm−3) was more than 10 times higher than that of FTO/Ti-Fe2O3 and Ti-sheet/Ti-Fe2O3. Analyses of the incident photon-to-current conversion efficiency (IPCE) and Faradaic efficiency indicated that Ti-felt/Ti-Fe2O3 showed higher PEC activity for the oxygen evolution reaction (OER) than FTO/Ti-Fe2O3. The enhanced PEC activity is ascribed to the higher donor density and moderate thickness of the Ti-doped Fe2O3 layer, which contribute to a short electron transport distance. Furthermore, the high loading of Fe2O3 on the Ti-felt substrate increased the photoabsorption in the UV and visible light regions and the photocurrent response at wavelengths near the band edge, even at low light intensities. This study provides new insights for preparing hematite photoanodes with higher PEC activity for the OER using a 3D porous substrate, rather than conventional 2D substrates.